Our Offer

We offer collaboration in the following areas:

Design, manufacturing, and testing of composite pressure vessels (for hydrogen storage, specialty gases, air)

Design and implementation of filament winding production lines for composite tanks in line with the latest trends

Consulting on the design and manufacturing of composite materials and prototype structures: technology selection, material selection, implementation support

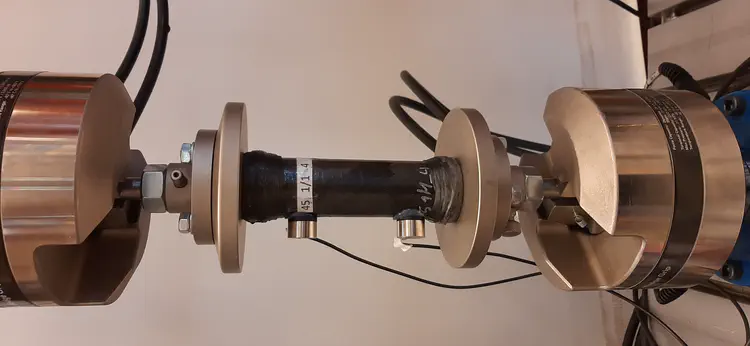

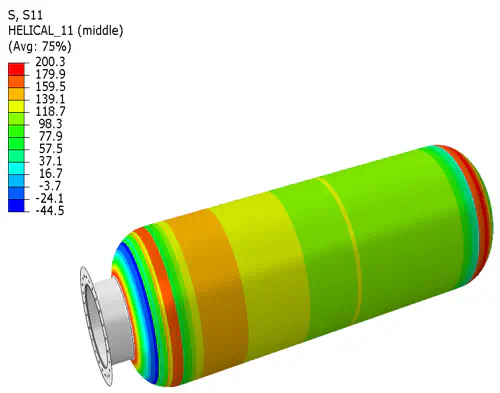

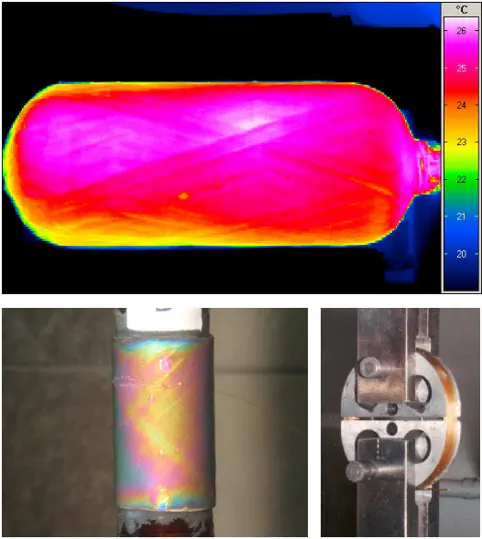

Material testing of composite structures

Preparation of project documentation (national, regional, European projects), support in the development of the substantive part

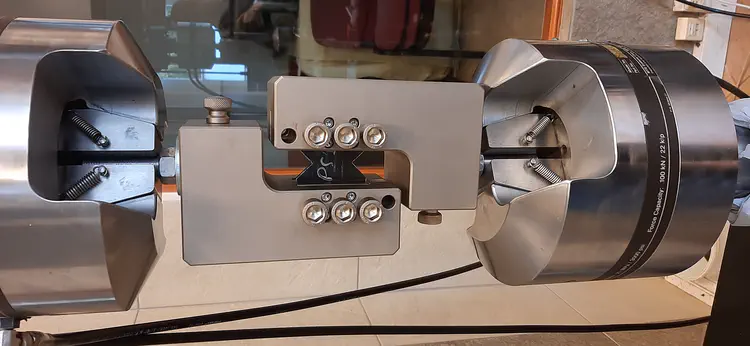

Consulting in the design of testing devices for measuring specified properties, in accordance with applicable standards (if they exist in the given case) or according to the client's procedures

Key laboratory equipment:

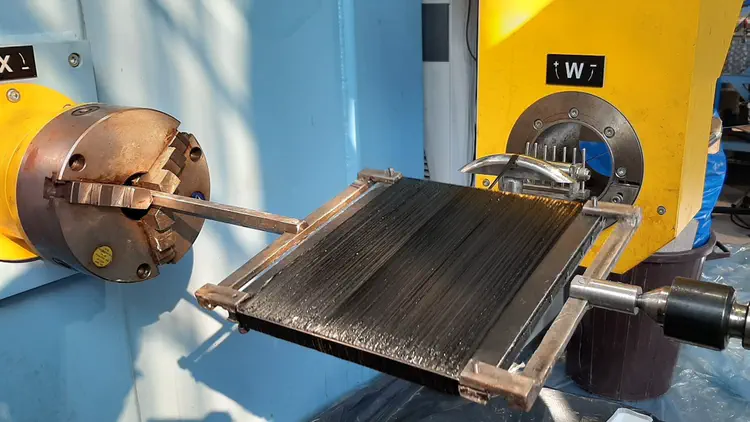

Mikrosam MAW 20 LS4/1 4-axis Winding Machine

A machine for manufacturing elements using wet filament winding (vessels, pipes, rings, etc.), equipped with the WindingExpert structure design software.

Selected projects to date:

CFRP tanks for hydrogen storage, capacity 6 liters, working pressure 700 bar

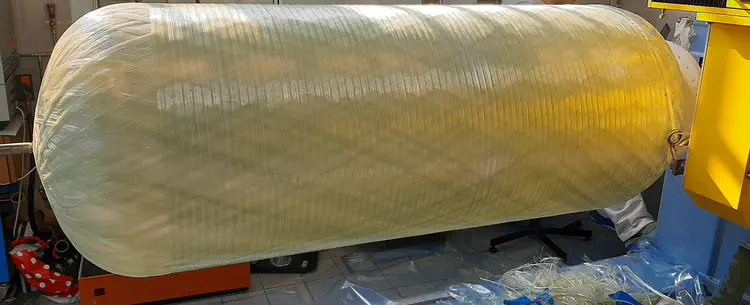

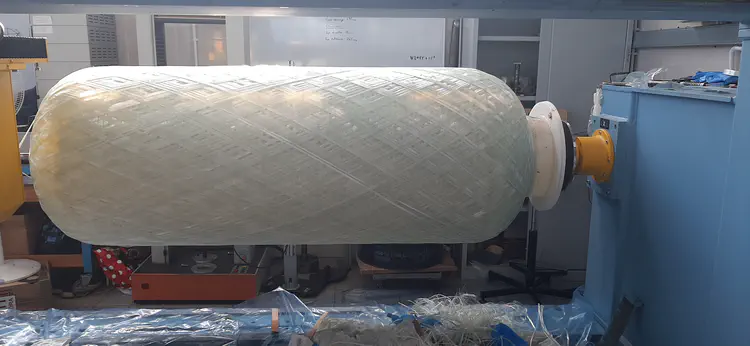

GRFP tanks for pressurized liquid storage, capacity 60 and 700 liters, working pressure 7 bar

Prototype double-walled cylinder for liquid hydrogen storage (LH2) based on DCPD resin

GFRP tanks for gas storage, capacity 8 liters, working pressure 100 bar

Composite cylinders for hydraulic actuators

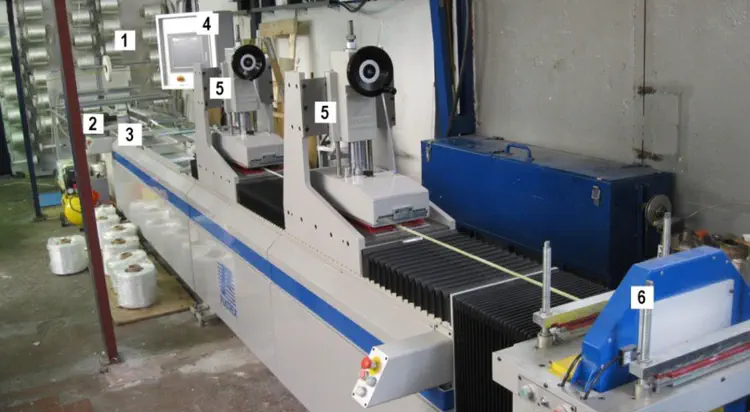

Px250T3 Pultrusion Line from PultreX (continuous manufacturing of composite rods and profiles) with accessories

Additionally, we possess the following equipment:

Creep testers – 10 stations available, maximum load 30 kN

Essential equipment for composite material manufacturing technologies: infusion laminating, hand laminating

Climate chamber

Acoustic emission

Sensors (strain gauges, optical fibers)

Vacuum dryers

Dryers

Muffle furnace

Freezer for prepregs

Autoclave

Hardness tester

Precision saw for sample preparation

Vicat and Martens testing stations

RTM applicator and impregnator set

We also have access to:

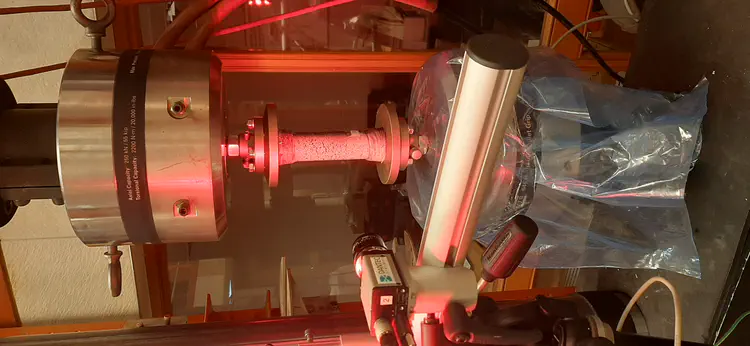

Strength testing machines (static tests, fatigue tests, tensile/compressive, torsion)

Microscopic sample preparation stations

Below are photos of selected projects.